Incorrect installation of fiberglass batt installation has been accepted for over 4 decades. Enforcement precedures have been weak along with the general knowledge of proper installation techniques by the contractors. As a building official and LEED accredited green builder from Connecticut my colleagues and I have realized the importance of the connection between education and enforcement. Our building depatment has tightened its enforcement of proper installation techniques while enhancing our communication with thecontractors.. All of us spend time educating the contractors to proper installation in wall assemblies, proper air sealing and infiltration techniques, and the requirements of the IECC. We do get some resistance due to the fact that improper techniques and the ignorance of proper air sealing has been accepted as the norm for so long. On the whole the buildersare accepting and enjoy the communication. Many discuss their issues during their design phases and ask our opinion of the building envelope. The State along with the Connecticut Energy Efficiency Fund has made a great effor tto provide seminars for Career Development regarding the fundamentals and requirements of the IECC. Your product critiques are extremely helpful in pointing out the strengthsand wealnesses of the different insulation and air sealing products and communication of those aspects to the building public. E.J. Palma, Branford, Connecticut

Blog Post

More Sloppy Cotton Batt Installations from Bonded Logic

What do you do when a green product doesn't live up to expectations? Here at BuildingGreen, we really want to see green building products succeed in the marketplace, and make it easy for professionals to find the best of the best.

But when we see something substandard, we feel it's important to point it out. To win the mainstream over to sustainability, we have to deliver on promises of reduced environmental burdens along with superior performance.

A little while back, I took Bonded Logic to task for flaws its Ultratouch cotton batt design and installation process.

The problems with Ultratouch

The worst flaw I found was that the product is too thin. After being compressed in bags for shipping from Ultratouch's Arizona plant, the post-consumer-denim cotton batts never regain their "loft." That means that insulation is going into wall and ceiling cavities with air spaces around it. Air that is completely stagnant insulates very well--at R-5, even better than Ultratouch's R-3.7. But air in wall cavities moves around with convection, contributing to heat loss and crippling the nominal R-value of the insulation. (Read more here on How Insulation Works.) I also found that the batts were too wide for 16-inch-on-center KD 2x4s (standard lumberyard kiln-dried sticks), leading again to air spaces due to poorly fitting batts.

Thirdly, I complained that the batts were really hard to cut. This was especially frustrating because the ill-fitting batts required a lot more cutting than a standard fiberglass batt.

SUPPORT INDEPENDENT SUSTAINABILITY REPORTING

BuildingGreen relies on our premium members, not on advertisers. Help make our work possible.

See membership options »The good news is that Bonded Logic is now perforating its batts at standard widths so that they are easier to cut for proper fitting. They haven't announced what those widths, are, however, and it seems like a tough problem. How standard are the sizes of the off-size stud cavities found in our buildings? Perhaps in new homes with designs optimized for manufactured material use they are standard, but in the retrofits and custom jobs that a lot of builders are doing today, I am not sure how useful these perforations will be.

Another piece of good news, according to a spokesperson I heard from, is that Ultratouch will also soon be available in different widths according to whether you're using wood or steel studs.

Bonded Logic still doesn't get it

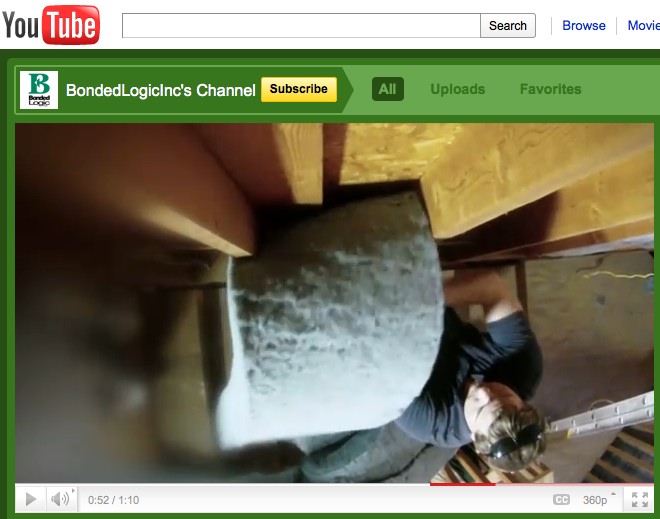

However, Bonded Logic still doesn't seem to get it when it comes to installation quality. Whether you're using fiberglass or cotton batts, exact fitting to cavity sizes is key. That means cutting insulation around electrical boxes, wiring, and also cutting it for the occasional cavity of a different dimension. What I've seen of this installation video is pretty good, but there's a flub in the Bonded Logic video publicizing its new perforated batts. As the screen capture shows, the installer is placing a batt in a cavity with complete disregard for the unusual shape of the cavity. The installation will result in a classic poor batt installation--lack of complete contact with all six sides of the cavity. What kind of attention are they putting into other irregular cavities?

I brought up this issue with the same Bonded Logic spokesperson in two successive emails, and did not receive a response. That was a couple months ago. The video is still up, so I'm taking Bonded Logic to task again.

The real installation culprit: fiberglass

To be clear, I like cotton insulation for several reasons, including Bonded Logic's recent move to post-consumer recycled jeans (previously it was pre-consumer denim), and the fact that it's much less unpleasant than fiberglass to work with--although unlike the folks in their videos I would still wear a mask to protect from dust that comes off the product, particularly during cutting. Also, the real culprit in batt insulation is fiberglass, which has been poorly installed by so many people in so many buildings for so many years--to the extent that one observer called for it to be banned. All the more reason, though, that we need to do better in the green products community.

What do you think? Please leave your comments below.

Published June 9, 2011 Permalink Citation

Yost, P. (2011, June 9). More Sloppy Cotton Batt Installations from Bonded Logic. Retrieved from https://www.buildinggreen.com/news-article/more-sloppy-cotton-batt-installations-bonded-logic

Add new comment

To post a comment, you need to register for a BuildingGreen Basic membership (free) or login to your existing profile.